It is difficult for our iron, spill, flow, and, sometimes with peaks, to hang the throw of hole soldering of those who tinker at home. Then, almost Almost is being assured to find out that soldering through holes was also a problem for a firm that made more than 60 million products with it.

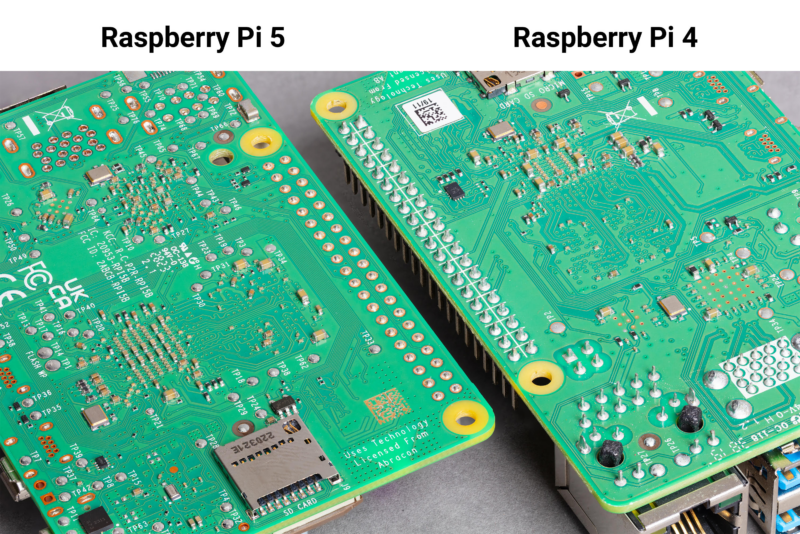

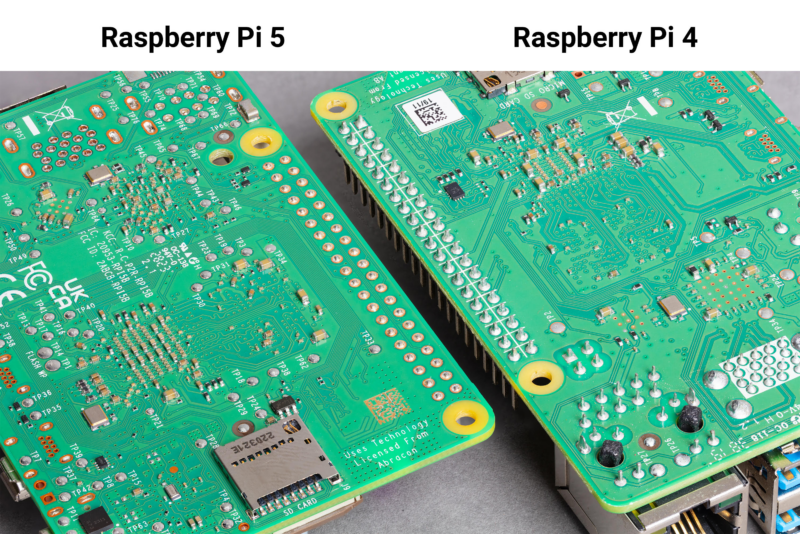

Rasberry pie boards have a combination of surface mount devices (SMD) and hole bits. SMD allows them to connect much smaller chips, resistant cars and other bits with their small pins, flat connectors, solder balls or other contacts. The things that are large, or the clumsy human hands are subject to rough powers, still needed soldering through holes, the leads are erected through integrated holes and solders and are applied to join them to connect and join them.

The Rasbery Pie Board has a 40 GPIO header on it, which requires holes with bits such as Ethernet and USB ports. They require a strong solder joint, which cannot be done in the same way as SMT (Level Mount Technology) with tools. “In the early days of the raspberry pie, these parts were handed over hand, and later through robotic placement,” Roger Thornton, director of applications for Rasbiri Pie, writes. A blog post. Then the boards had to go through the follow -up Wave soldering Step

Now the PI boards have their small pieces and large pieces at the same time, which is an interference reefu soldering process, which is started with Rasbery Pie’s UK manufacturing partner, Gold. After adjusting the components, adjusting the solder stansel, and the connector, the board makers can keep and save all their components at the same stage.